Two Robotic Integrations That ALMOST Went Wrong

For every robotic integrator, there’s the plan, and then there’s reality. It’s just the nature of the industry. What sets our team apart is what happens when those two don’t perfectly align.

At QComp, our engineers don’t just build systems to spec; we go onsite, observe the actual production environment, and ensure everything functions exactly as intended. But sometimes things change between concept and implementation. A slight tweak to a part’s orientation, a lighting condition that changes, or a shift in material behavior that seems minor to the facility can completely disrupt a robot’s performance.

That’s where our team’s experience and resourcefulness come in. Rather than retooling, delaying deployment, or completely reprogramming a cell, we adapt with creative thinking that keeps the project on track.

Here are two examples where things didn’t go quite as planned, and how QComp found a solution.

RELATED: Overcoming the Challenges of Robotics Integration

Steel Tubing: Repositioning the Problem

Challenge

A bin-picking application for steel tubing seemed straightforward until real-world testing revealed an unexpected issue: The steel tubing the robot was supposed to pick and place was inconsistently oriented, causing issues with picking and placing the tubes in the proper position. Additionally, the vision system struggled to perform reliably due to unpredictable ambient lighting in the facility.

QComp Solution

QComp engineers pivoted quickly by adding a simple repositioning stand. After rough picking a part from the bin, the robot places each part on the stand and properly repicks with the aid of sensors. Typically, adding steps to a process means slower production lines. However, the added step delivered a more reliable and efficient outcome, improving throughput and reducing costly rework on the backend.

To tackle the lighting challenge, the team made adaptations in the field: they fully encapsulated the cell using a canvas-like cover to block out all ambient light. This straightforward but effective solution ensured the vision system could function consistently, eliminating false reads and enabling accurate picks.

Lawn Bags: Solving Stackability Without Tooling Changes

Challenge

When handling rigid materials of the same size, shape, and orientation, placing them with a robot is relatively simple. But in this case, QComp was tasked with stacking large flexible yard refuse bags into Gaylord containers, nine at a time. The challenge? The bags were too lightweight, maleable, and unpredictable, causing them to shift when landing, and the stacks slumped inconsistently.

QComp Solution

Instead of overengineering a fix, QComp’s team saw an opportunity for smarter programming. During factory acceptance testing with the customer onsite, our engineers modified the robot's drop sequence. Rather than placing all nine bags at once, we split the task into three smaller placements of three bags each. This minor change in the robot's motion resulted in a major improvement in performance. The bags stacked perfectly, and the customer was thrilled.

Even better, the solution required no hardware changes, no new tooling, and no added fixtures — just clever programming and real-time adaptation during testing.

View Non-Woven Automation Solutions

Solutions for Complex Automation Challenges

Even with thorough planning, programming, tooling, and testing, real-world conditions can introduce unexpected variables, especially in complex robotic integrations. How your automation partner responds and solves those challenges is what sets them up for success or failure.

At QComp, we conquer complexity. Our engineers are trained not just to build robotic systems that perform highly complex tasks, but to think critically when conditions change. That in-the-moment problem solving, guided by engineering intuition and years of experience tackling complex challenges, is how we ensure every system we deliver performs as promised.

We’re here to help you solve automation challenges in the real world. Contact our team to talk through your complex robotic handling needs.

Share this

You May Also Like

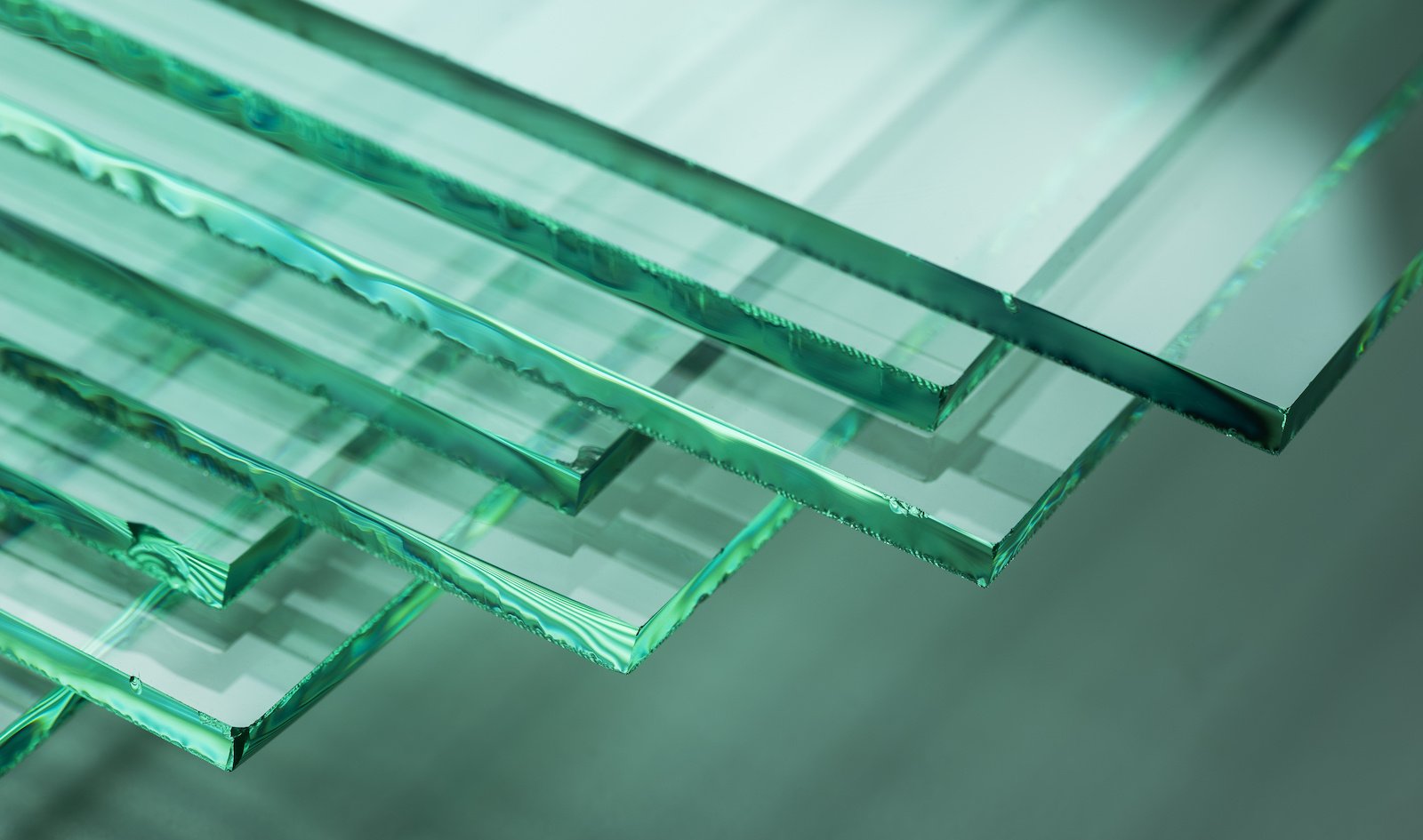

4 Main Types of Flat Glass Suitable for Robotic Automation

Understand the 4 main types of flat glass — float, tempered, laminated, insulated — and how robotic handling improves efficiency and reduces breakage.

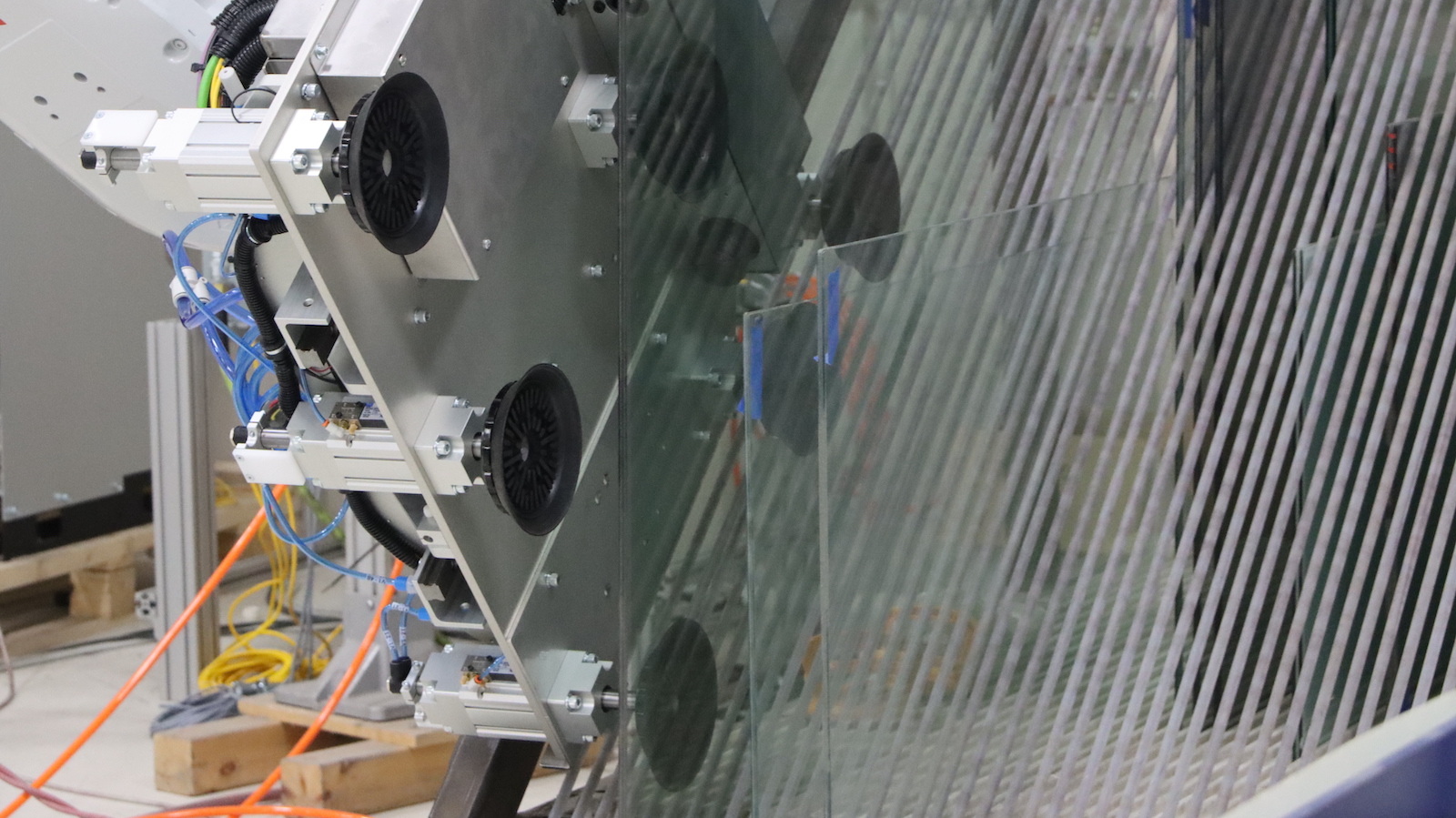

Cable Management in Glass Line Automation: An Overlooked Necessity

Learn how QComp and BizLink tackle cable durability, uptime, and safety challenges in glass robotic automation, redefining efficiency in glass manufacturing lines.

Automation Challenge: Glass Industry Harp Rack Loading

Learn how QComp’s innovative harp rack unloading automation improves glass industry safety, reduces risks, and boosts precision and productivity.