Expert Robotic and Automation Services

Your Service Partner for the Entire Automation Lifecycle

Going Beyond Integration

As an authorized dealer and service provider for ABB, FANUC, and Stäubli industrial robots, we pride ourselves on helping your line stay up and running with our attentive service and skilled engineering staff.

Whether or not we provided your robotic integration, QComp offers the service, support, and parts to help you get the most from your automation investment. Contact us to discuss your needs.

Authorized distributor & Service Provider

Qcomp is a trusted distributor of ABB, FANUC, and STÄUBLI industrial robots, offering direct robot sales- no integration required.

Safety First

QComp is A3 certified by the Association for Advancing Automation, ensuring compliance with industry-leading standards in robotics and automation.

Robotic Services Offered by QComp

QComp provides comprehensive technical services to ensure optimal performance. If your cell is integrated by QComp, you’ll have a dedicated account manager who understands your business and coordinates all your service and support. Plus, 24/7 access to expert help for troubleshooting and resolving technical issues.

But we don’t stop there…

Onsite Services

Technical services, including installation, maintenance, and repair of automation equipment.

Predictive Maintenance

Uses data and analytics to anticipate equipment failures before they happen, reducing downtime and repair costs.

Automation Services

Comprehensive solutions for automating manufacturing processes, from design to implementation.

Robotic/Automation Training

Hands-on and classroom training to upskill your teams, helping users operate, maintain, and troubleshoot robotic automation technologies.

Cell Simulations

Virtual modeling of robotic cells to test and optimize performance before physical deployment.

Remote Monitoring

Real-time system oversight from a distance, enabling proactive maintenance and issue detection.

Total Cell Upgrades

Modernization of robotic cells (controllers, arms, etc.) with updated hardware and safety systems for improved performance and compliance.

Safety Evaluations & Audits

Benchmark assessment of safety practices and systems to ensure compliance and identify areas for improvement.

QComp’s service team has been outstanding to work with. They’re responsive, knowledgeable, and always go the extra mile to keep our systems running smoothly.

Maintenance Manager

Custom Service Manufacturing

Our process streams utilize lidding, bundling, packing, and palletizing. QComp Technologies supports us every step of the way in timely troubleshooting and innovative solutions for improved performance.

Process Engineer

Major Wet Wipe Producer

I am impressed with the professionalism of the staff. Not only are they customer-focused, they are also knowledgeable and able to support the equipment. QComp's engineers play a key role in keeping our cell running and can easily make any changes we may need. They are very helpful and explain things very well.

Plant Engineer

Leading Baked Goods Manufacturer

Contact Us

We’re up for the challenge! Complete the form below and we’ll be in touch soon.

Latest QComp News

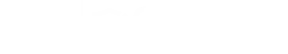

4 Main Types of Flat Glass Suitable for Robotic Automation

Understand the 4 main types of flat glass — float, tempered, laminated, insulated — and how robotic handling improves efficiency and reduces breakage.

Cable Management in Glass Line Automation: An Overlooked Necessity

Learn how QComp and BizLink tackle cable durability, uptime, and safety challenges in glass robotic automation, redefining efficiency in glass manufacturing lines.

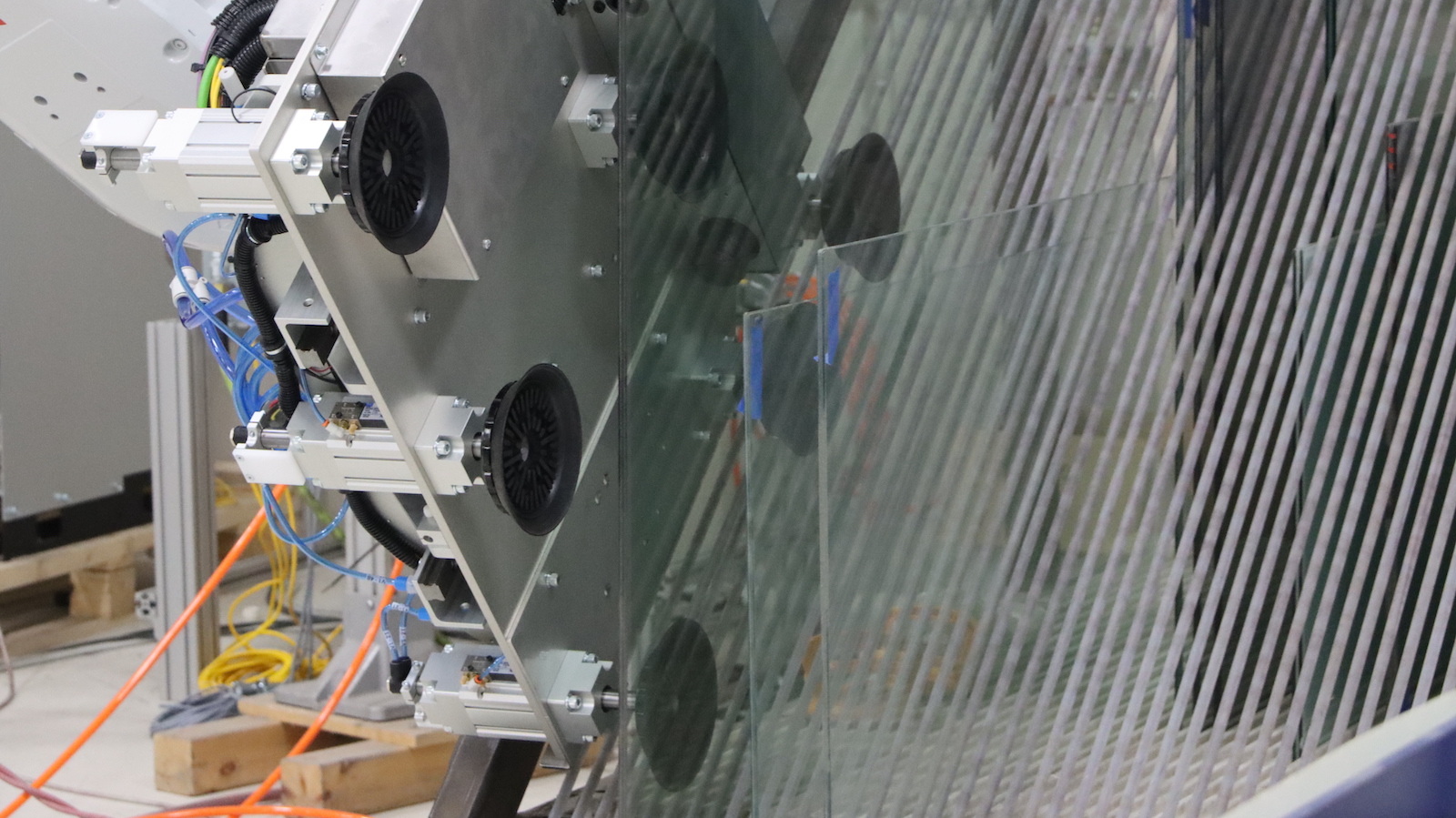

Automation Challenge: Glass Industry Harp Rack Loading

Learn how QComp’s innovative harp rack unloading automation improves glass industry safety, reduces risks, and boosts precision and productivity.