Protect Automation ROI & Prevent Downtime With Proactive Service

When a customer calls me at 6 or 7 p.m. because their robot cell just went down, the first thing I think is: This probably didn’t have to happen. Most breakdowns we see in the field aren’t surprises. They’re symptoms that went unrecognized, unreported, or unaddressed.

And at a time when capital budgets are tight and teams are pushing existing equipment harder than ever, the stakes are even higher. Reliability isn’t a performance metric anymore: it’s a financial strategy.

Since we launched our new Service & Support program earlier this year, we’ve seen customers adopting a more proactive, preventive approach.

That’s encouraging, because the fastest way to maximize the longevity and ROI of any automation system is simple: Don’t wait until something breaks.

Invisible Culprits That Erode ROI

Most systems don’t fail because of one big dramatic event. They fail because of dozens of small variables that pile up over time: wear items run longer than they should be, a lubrication cycle missed during a shift change, a belt that’s been squealing for two weeks but no one flagged it.

From the service side, the patterns are clear.

1. Wear Items Are Ignored Until They Fail

Belts and bearings are always at the top of the list. They’re inexpensive, but when a plant is losing tens of thousands of dollars per hour in downtime, that belt suddenly becomes the most expensive part in the building.

CASE STUDY: When a Belt Costs More Than its Price Tag

A customer’s automated line cycled through a third-party belt 20+ times annually. The original vendor's long lead times meant repeated downtime, forcing the plant to pay expedite fees that dwarfed the belt’s actual cost.

QComp reverse engineered the belt and sourced a local vendor who could produce the belt in half the time, reducing both downtime and expedite charges. And now, we’re collaborating with the vendor to engineer an improved solution that addresses the root cause of accelerated wear.

2. Maintenance Isn’t Consistent

Some plants have deep engineering benches. Others are just getting started with automation. When basic preventive maintenance (PM) like lubrication, tension adjustments, or sensor checks slip, system life shortens faster than people expect.

3. Operators Don’t Recognize Early Warning Signs

Signals show up early: missed picks, new noises, drifting positions. But many operators only know the start-up steps, not what “normal” should look like. The disconnect is understandable, but it can be costly.

Why Manufacturers Don’t Stock Spare Parts (Even When They Should)

One proven way to minimize downtime is to keep spares on hand for the items that predictably wear out and need replacement. Yet not everyone chooses to keep parts in stock. From what I see, what seems like a preference for risk-taking usually comes down to three things:

- Cost of carrying inventory

- Wear part lifecycles go unmonitored

- Lack of clarity about wear patterns and expectations

When your robot cell predictably runs through a belt every month, it’s difficult to justify the cost of downtime over keeping a spare belt in stock. Yet the hesitation to keep spares on the shelf remains.

That’s why QComp provides a list of critical spares and lead times, so customers are aware from Day 1 what their systems need to stay up and running at peak performance. It’s why we advise on maintenance and replacements based on our own extensive experience.

But at the end of the day, it’s the customer who decides where downtime sits in their cost structure.

Different Teams, Different Realities

One dynamic we see often is the disconnect between the people involved during system design and the people who actually live with the system every day.

During design, we’re talking to engineering leaders. They fully understand cycle rates, system behavior, robot loads, and maintenance expectations. But once the system hits the floor, the primary users may be operators who were trained only briefly and may not have automation backgrounds.

When a plant has no in-house engineering or maintenance depth, small things may go unnoticed (or unreported) longer, and the risk of avoidable failure grows.

On the other end of the spectrum, plants with an established automation culture often maintain their systems beautifully. They catch issues early, replace parts on schedule, log wear patterns, and plan for predictive maintenance to avoid surprises.

What We See Immediately When We Visit a Site

Whether we’re on-site for a routine check or an emergency call, we can usually read the situation fast:

Signs of a well-maintained, cared-for system:

- Clean joints without buildup

- Lubrication applied where and how it should be

- Belts run quietly and smoothly

- Robot motion that’s tight and repeatable

Signs that trouble’s brewing:

- Dirt and debris coat the robot

- Metal shavings near joints

- Squealing or rattling sounds

- Drift or lag in moves

- Dry or neglected lubrication points

CASE STUDY: When an Oil Change Becomes a 6-Figure Issue

After months of skipped oil changes, it’s typical to see robot arms develop a gradual drift from programmed points. The friction and wear don’t announce themselves dramatically; they quietly erode precision until tight-tolerance work becomes impossible.

By the time accuracy issues force a shutdown, worn components may require full replacement rather than routine service. What should have been a scheduled maintenance task becomes an unplanned capital expense.

None of this is about blaming operators or maintenance staff. It’s about understanding how small indicators point to bigger issues long before a breakdown.

Remote Support: One of the Most Underrated Tools

Not every problem needs a site visit, and plenty shouldn’t.

Recipe updates, pallet pattern tweaks, diagnostic checks, and certain logic adjustments can often be handled remotely. We regularly write a new program or pattern here, send it over, and walk the team through it without ever stepping on a plane.

When you’re running three shifts, shaving even an hour off downtime makes a real financial difference.

Five-Minute Fixes, No Flight Necessary

QComp can solve many issues via remote diagnostics in minutes rather than hours or days: issues like sensor failures, camera alignment issues, and controller glitches. We log into the system, identify whether it's a sensor reading incorrectly, a camera that’s shifted, or a board requiring replacement, and guide the customer through the fix in real time.

For issues that once meant waiting for a site visit, remote support now delivers immediate troubleshooting that helps keep lines running.

Is There a Low-Maintenance Option?

Every robot cell has joints, bearings, belts, and wear points. Those are mechanical realities, not design choices. What does differ is how well a system is cared for and how disciplined the plant is with PMs.

We design the system to last. But every robot, conveyor, and EOAT needs consistent attention if you expect long-term reliability.

If You Remember Only One Thing…

Perform the preventive maintenance as recommended by the robot manufacturer. That’s the whole game. Downtime is too costly. Rush fees and emergency site visits only add to the pain. When you follow the recommended PM schedule, you avoid most issues entirely.

We can and will redesign a pattern, replace a component, or help diagnose a tricky problem. But nothing stretches the life of a system longer than the scheduled care it was designed to receive.

Why Work With One of the First ABB Value Providers?

QComp was one of the first three providers in the world to earn the status of ABB Value Provider. That means:

- We can escalate robot issues directly to ABB

- We have priority access to ABB’s service and engineering resources

- We’re vetted for both technical competency and service rigor

- Customers gain a higher level of confidence in long-term support

Our ABB Value Provider designation isn’t merely a badge; it’s proof of our commitment to deep, expert partnerships.

Making Reliability Your Financial Strategy

Automation is a long-term competitive play. But equipment longevity doesn’t happen by accident. It happens through:

- Consistent preventive maintenance

- Timely replacement of wear items

- Training operators to report what they see

- Keeping essential parts on hand

- Using remote support before small issues become big ones

If you take care of your system, you can expect predictable performance over time. No matter how complex the system or how demanding the production environment, the facilities that get the most from their automation are the ones that stay ahead of issues rather than reacting to them.

The good news is, you don’t need massive budgets or major system overhauls to do that. You just need the right support, the right spare parts strategy, and a partner who understands how to keep high-complexity cells running as reliably as they were designed to. That’s where our services come in. If you’re looking to strengthen uptime, protect your investment, or get more life out of the automation you already have, explore how our service team can help.

Share this

You May Also Like

More Than Integration: QComp Delivers Robot Parts, Service & Direct Sales

QComp is a trusted source for OEM robot parts, expert service, and direct robot sales from ABB, FANUC, and Stäubli.

QComp: Proud to Be One of the First ABB Value Providers in the World

QComp was the third company in the world to join ABB’s Value Provider Program. Discover how decades of partnership and proven expertise help us deliver smarter, certified automation solutions that conquer complexity.

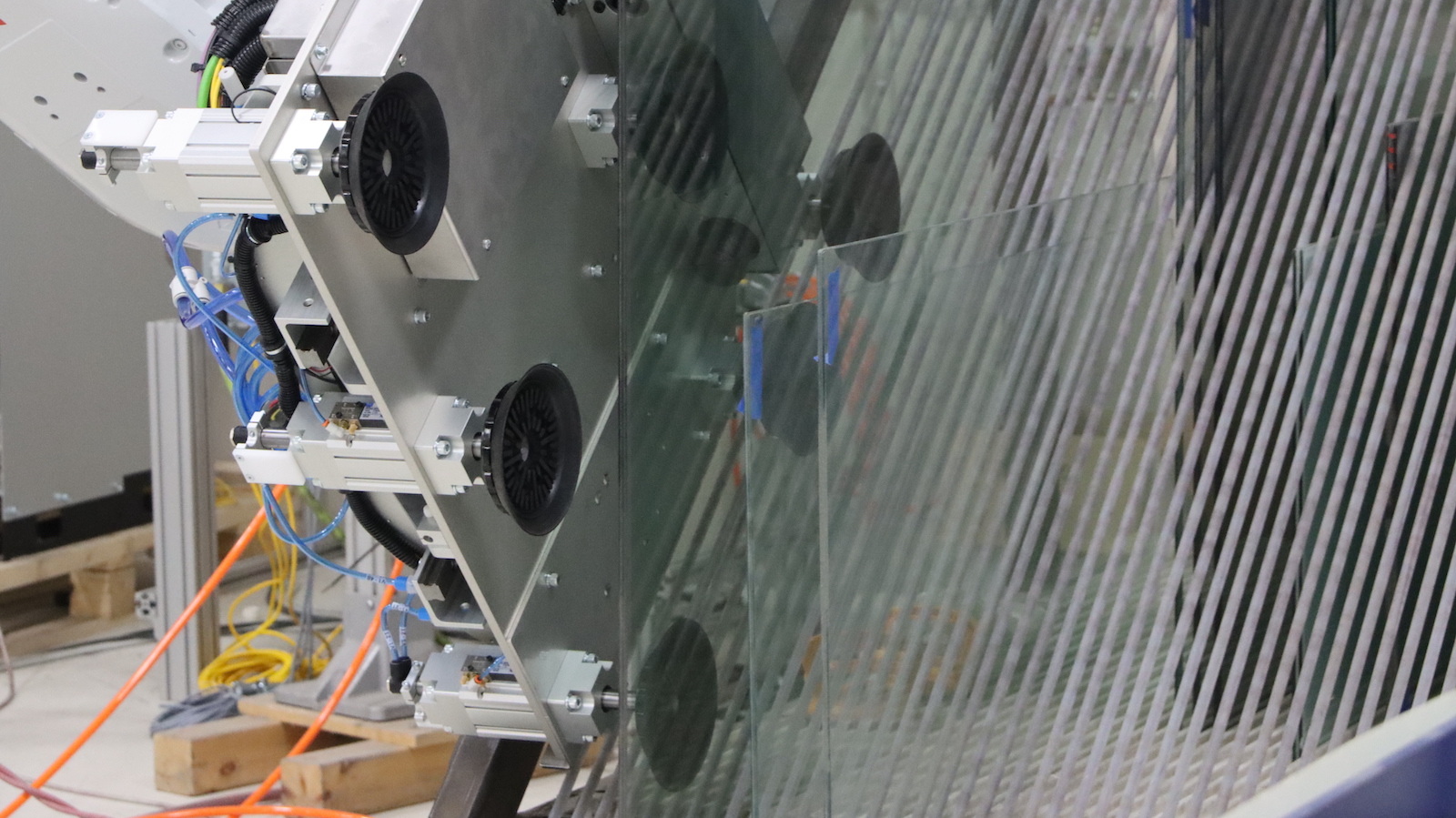

Automation Challenge: Glass Industry Harp Rack Loading

Learn how QComp’s innovative harp rack unloading automation improves glass industry safety, reduces risks, and boosts precision and productivity.