Jumbo Glass Robotics

Expanding the limits of what robots can do is built into the QComp DNA.

And in the glass industry, our team takes a holistic approach to engineering, pushing the limits of what technology can do.

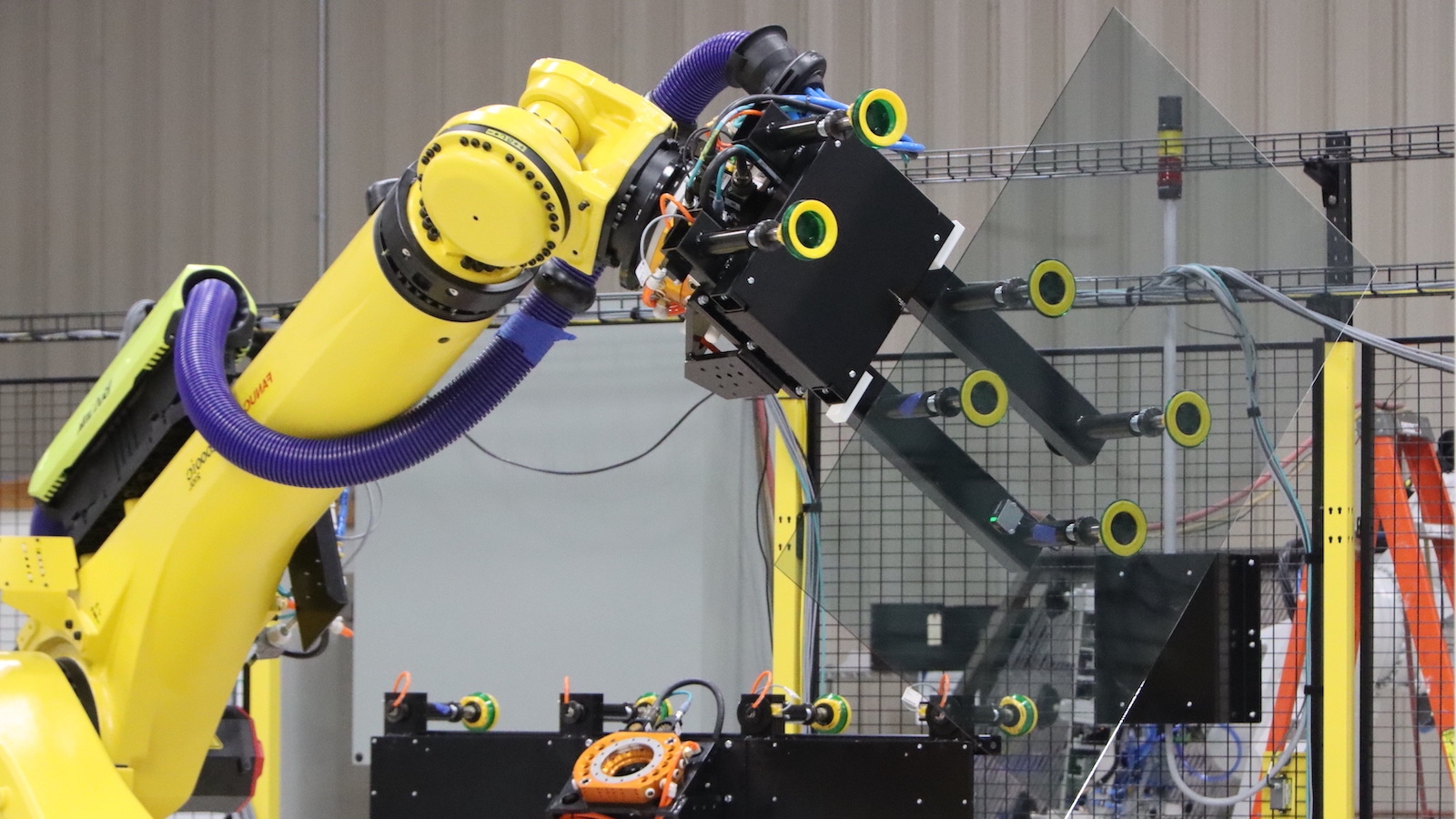

Earlier this year our team tackled our biggest glass project yet: a large-capacity robotic glass assembly rack loading system where racks could be slotted in L-frame or A-frame styles.

This robotic system can automatically pick a full-size range of rectangular and shaped glass, including insulated glass units and apply cork separators prior to rack-loading for shipping or additional downstream processing.

Laser-guided product size determination informs which end-of-arm tool is required to safely pick the glass and the tool changes occur automatically. Along with this, applied robotic innovation enabled step-change improvements in quality, productivity and cost.

The ability to pick and pack an extremely wide range of glass and glass assembly sizes, including shapes and assemblies greater than 1000 pounds is pushing robotic glass technology limits! Nonetheless, safe system operation was assured as part of this innovation and was a key driver and goal of this system development. Product size detection, combined with parametric programming, enabled automated tool changing to optimize system flexibility and throughput. Watch above to see this robot and cell in action.

Are you ready to push the boundaries with us? To learn more about our 6-step customized solutions process, click here. Or reach out to us to begin the conversation.

"It went smoothly, and just as expected. It’s just easy to work with the QComp team."

- Doug L. Jumbo Glass Partner

Share this

You May Also Like

Improving Glass Industry Safety: How Automation Helps Prevent Injuries

How to improve safety in the glass manufacturing industry using robotic automation. Explore how a leading robotics integrator is solving the toughest challenges.

4 Main Types of Flat Glass Suitable for Robotic Automation

Understand the 4 main types of flat glass — float, tempered, laminated, insulated — and how robotic handling improves efficiency and reduces breakage.

Optimizing Glass Line Load and Unload with Robotic Automation

Robotic glass line load/unload automation improves safety, efficiency, and productivity. Discover robotic solutions to optimize handling in glass manufacturing.