Automation Meets Opportunity: What We Learned at GlassBuild America 2025

GlassBuild America 2025 made one thing clear: Automation in the glass industry isn’t on the horizon. It’s happening now. From discussions about high-payload robotic handling to conversations around flexible vision systems, glass manufacturers and fabricators were looking for innovations that solve real-world manufacturing challenges.

The industry’s mindset has moved from “what if” to “what’s next.” Across the floor, discussions centered on actionable automation: how to deploy systems that address safety risks, workforce gaps, and production agility today.

As engineers who live and breathe this work, we walked away energized and with a clear view of where glass automation is headed next. Here are five takeaways that really stood out to us on the show floor.

1. Automation Has Gone From Curiosity to Necessity

This year’s GlassBuild America made one thing clear: automation has crossed the line from “interesting” to essential. From small fabricators to global glass producers, everyone we spoke with wanted to understand how robotics could help them solve their labor, safety, and production challenges.

Some visitors came to our booth who don’t have robotics on their lines. Others have implemented robotic cells and came looking to see what’s next. But the motivation was the same: staying on the leading edge.

In an industry where you’re lifting, tilting, and moving materials that can weigh over 1,000 pounds, safety and consistency aren’t optional. Automation is becoming the best, most sustainable way to protect workers, increase output, and stay competitive.

RELATED: Cable Management in Glass Line Automation: An Overlooked Necessity

2. Safety and ROI Are Part of the Same Conversation

When we talk about automation ROI in glass, we can’t just talk about throughput or labor cost anymore. Safety is ROI.

Every year, we see more companies prioritizing automation because they’ve had one too many close calls (or worse, one serious injury), and they don’t want to risk it again.

“You can’t always measure peace of mind in dollars, but when a robot takes a worker out of harm’s way, the value is immediate.”

Katie Miner, President, QComp Technologies

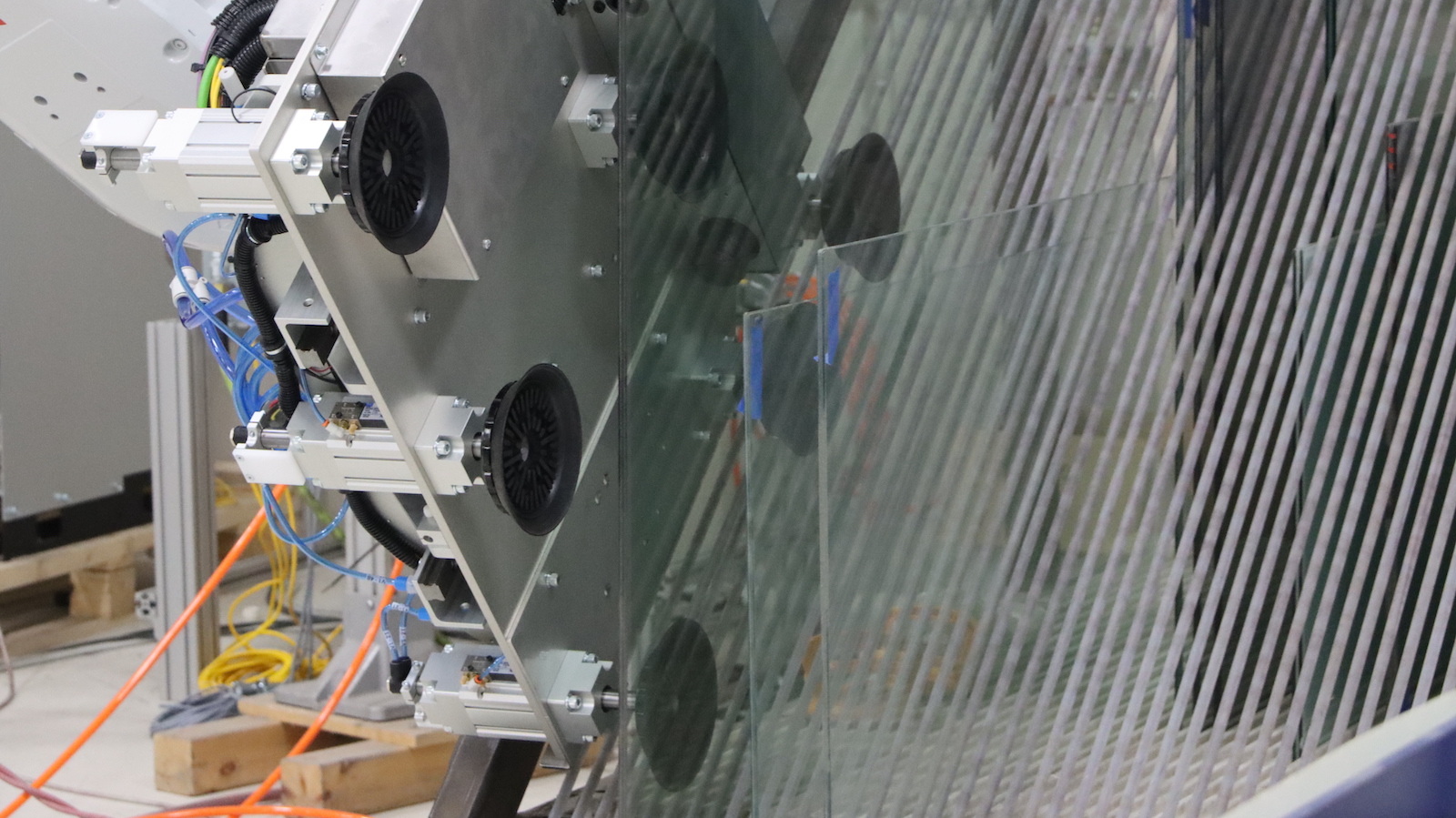

Modern glass-handling cells are engineered with safety in mind from the start. Parametrically programmed robots handle variable sheet sizes; vision systems guide placement with millimeter accuracy; and end-of-arm tooling adapts to each product’s geometry. These design layers do more than reduce breakage. They help businesses mitigate risk.

3. Flexibility Drives Every Investment Decision

If we had to pick one theme that came up in nearly every conversation, it was flexibility.

Glass manufacturers want automation that can handle new shapes, coatings, and SKUs, including the ones that don’t exist yet. Flexibility to adapt production equipment quickly between SKUs is essential to moving the product and keeping customers satisfied.

That’s why QComp Technologies’ modular design approach resonated so strongly. We often start with one high-impact section of a production line, such as a racking cell or boxing station, and help customers build from there. By designing systems with scalable architecture, we make it possible to automate in phases and still end up with an integrated, future-ready process.

For many customers, this phased path to automation is the most practical way to balance budget, risk, and ROI.

4. Vision Systems Are Redefining Precision in Glass Handling

Vision technology was on the rise at GlassBuild 2025, and for good reason. When a system can properly “see” where each sheet begins, ends, and varies in size or coating, it can pick and place safely and consistently, even across product changes. Anyone who’s automated handling of transparent materials knows the challenges: reflection, refraction, and inconsistent edges can throw off even the best equipment.

Our success in this space comes from years of fine-tuning how the data, applications, and robots communicate and interpret those conditions. It’s about much more than the cameras; it’s about how the vision data feeds the robot’s decision-making, and how the systems integrate and perform under real-life conditions.

Along with specifications, integrations, and performance requirements, our team’s proven experience drives QComp’s success in reducing breakage and increasing throughput using vision systems. (And we broke a lot of glass figuring it out so our customers don’t have to.)

5. Collaboration Is the Key to Adoption and Long-Term Success

One thing hasn’t changed: automation works best when people are part of the process from the start.

We often tell customers, a robot can replace repetitive motion, but not a motivated robot operator. Successful projects happen when plant teams are involved early: when operators walk through our shop, see their system being built, and have a chance to ask questions. That’s how buy-in happens.

We also train robot operators for success after installation. The goal isn’t to replace jobs, it’s to upskill people and improve the employee experience. When teams understand how to run, maintain, and troubleshoot their systems, they take ownership. And when ownership takes hold, performance follows.

That alignment between people and technology is key to making automation sustainable.

Looking Ahead

For us, GlassBuild 2025 reinforced how much opportunity still exists in the glass sector. Manufacturers are facing real challenges: labor shortages, safety risks, and inconsistent materials. And they’re looking for partners who can help them navigate the complexity.

QComp was built for the challenge. Our engineers, programmers, and project teams design custom systems that perform exactly as promised. We build systems that handle the jobs others can’t or won’t attempt, and offer solutions for glass, window, and door manufacturers.

As we look to 2026 and beyond, we see a glass industry that’s ready to automate smarter, safer, and faster. The technology is here. The confidence is growing. And the results speak for themselves.

Whether you’re exploring your first automation project or expanding an advanced line, you need a partner who can help you get it right. Contact QComp to start a conversation about your goals and how automation can make your operation safer, smarter, and more efficient.

Share this

You May Also Like

Cable Management in Glass Line Automation: An Overlooked Necessity

Learn how QComp and BizLink tackle cable durability, uptime, and safety challenges in glass robotic automation, redefining efficiency in glass manufacturing lines.

QComp in 2026: Built on Experience. Engineered for What’s Next.

QComp is an experienced robotic systems integrator helping global manufacturers conquer complex automation challenges across glass, consumer goods, nonwovens, food & beverage, and beyond. Learn who we are in 2026.

Automation Challenge: Glass Industry Harp Rack Loading

Learn how QComp’s innovative harp rack unloading automation improves glass industry safety, reduces risks, and boosts precision and productivity.