Luke Hanson

Project Engineering Manager

Luke Hanson has always been interested in any mechanical device and how things work. After high school, he was a certified automotive repair technician and eventually moved into the industrial maintenance trades. Working for a Wisconsin-based global manufacturer, Luke transitioned from the trades to a newly formed team that designed and built equipment aimed at improving processes and reducing cost at multiple facilities worldwide.

Luke got his start in robotics integration over 20 years ago, taking on his first robotic pick-and-place project. What seemed to be nothing more than another lean manufacturing or ergonomics improvement venture was the start of an industrial automation career. Luke was exposed to material handling, metal finishing, assembly, and spraying applications and with his team, pioneered several industry-first robotic applications. Several automation projects later, he knew industrial automation was his thing.

In 2020, Luke joined QComp in a role similar to his previous position but with several new applications. The glass and wet wipes applications presented new and refreshing challenges. Since then he has been promoted to the Project Engineering Manager and is a valuable member of the QComp Leadership team.

When not at QComp, Luke enjoys hunting, fishing, and cars.

Credentials / Certifications / Education

- Bachelor of Science in Mechanical Engineering- UW Platteville

- A3 Certified- Robotics Integrator

History with the Company

Luke Hanson joined QComp in 2020 as a Controls/Project Engineer and quickly advanced into a lead role.

In January 2023, he transitioned into the position of Project Engineering Manager, where he continues to guide complex automation projects and support cross-functional engineering initiatives.

In 2024, Luke became a member of QComp’s leadership team, contributing to strategic planning and organizational development while helping shape the future of QComp’s automation capabilities.

Areas of Expertise

-

FANUC robotic programming & deployment, including:

-

2D & 3D iRVision

-

iRPickTool

-

Coordinated motion applications

-

Force control technologies

-

-

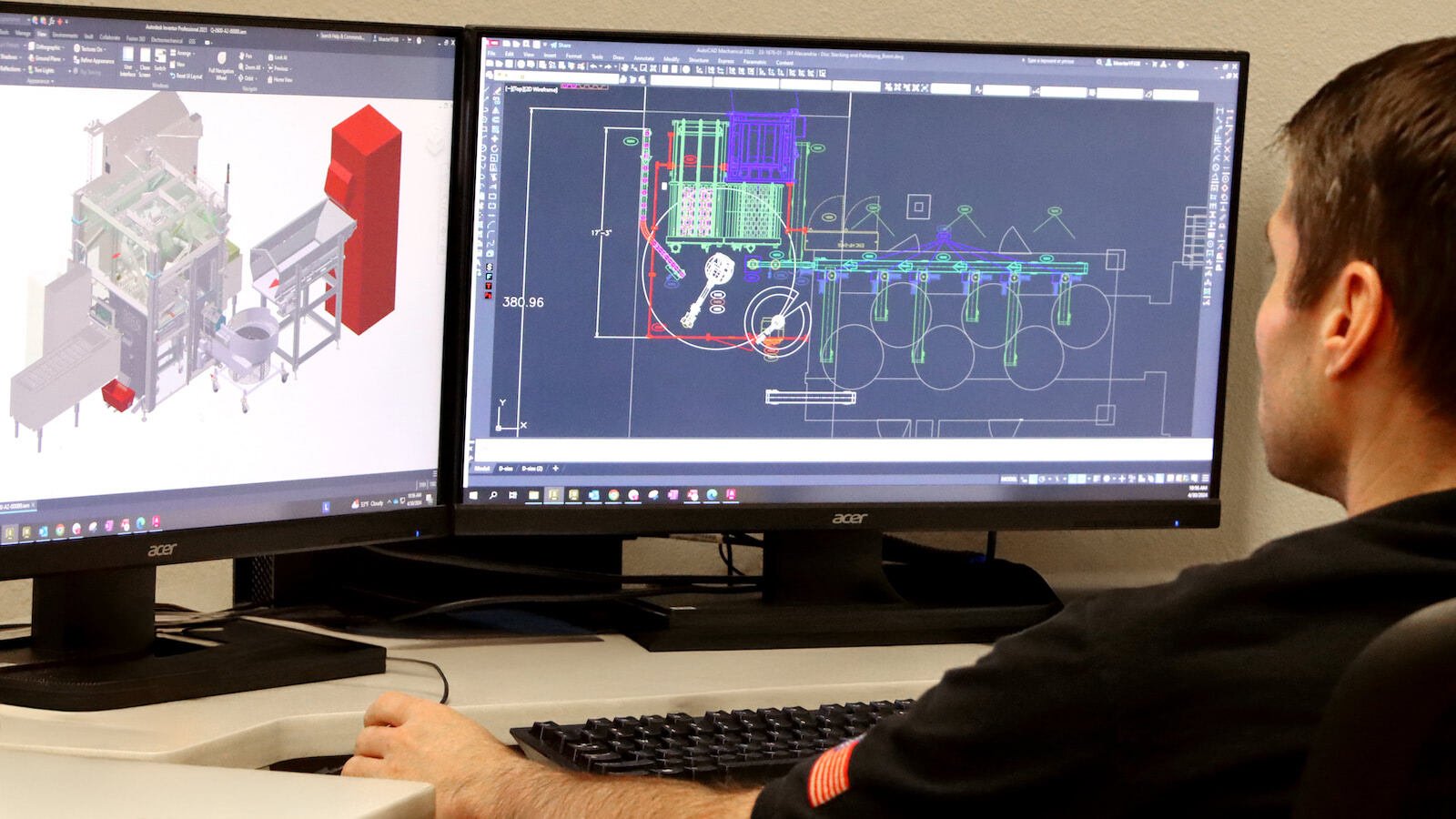

Mechanical design for complex automated systems

-

Advanced troubleshooting & root-cause analysis across diverse industrial automation environments

-

Project engineering & technical leadership, guiding multidisciplinary engineering teams through complex automation initiatives

-

Cross-functional collaboration, working closely with sales, controls, mechanical design, and project management to drive successful outcomes

-

Clear communication & customer engagement, translating technical concepts into practical solutions for internal teams and client stakeholders

-

Continuous improvement mindset, focused on process efficiency, system performance, and long-term equipment reliability

“Great engineering is equal parts curiosity, discipline, and teamwork.”

Luke Hanson

Why QComp?

I have the privilege of working alongside talented, hardworking people who are committed to excellence. I’m energized by tackling complex challenges — whether it’s reducing equipment cycle times, refining motion paths, or solving intricate mechanical problems — and turning them into reliable, high-performing automation solutions.

Articles from Luke

Two Robotic Integrations That ALMOST Went Wrong

See how QComp engineers solved unexpected robotic integration challenges with smart fixes that boosted reliability and efficiency.

Overcoming the Challenges of Robotics Integration

Explore considerations when integrating robotics into an existing production line and potential challenges including space constraints, utilities, safety, and more.

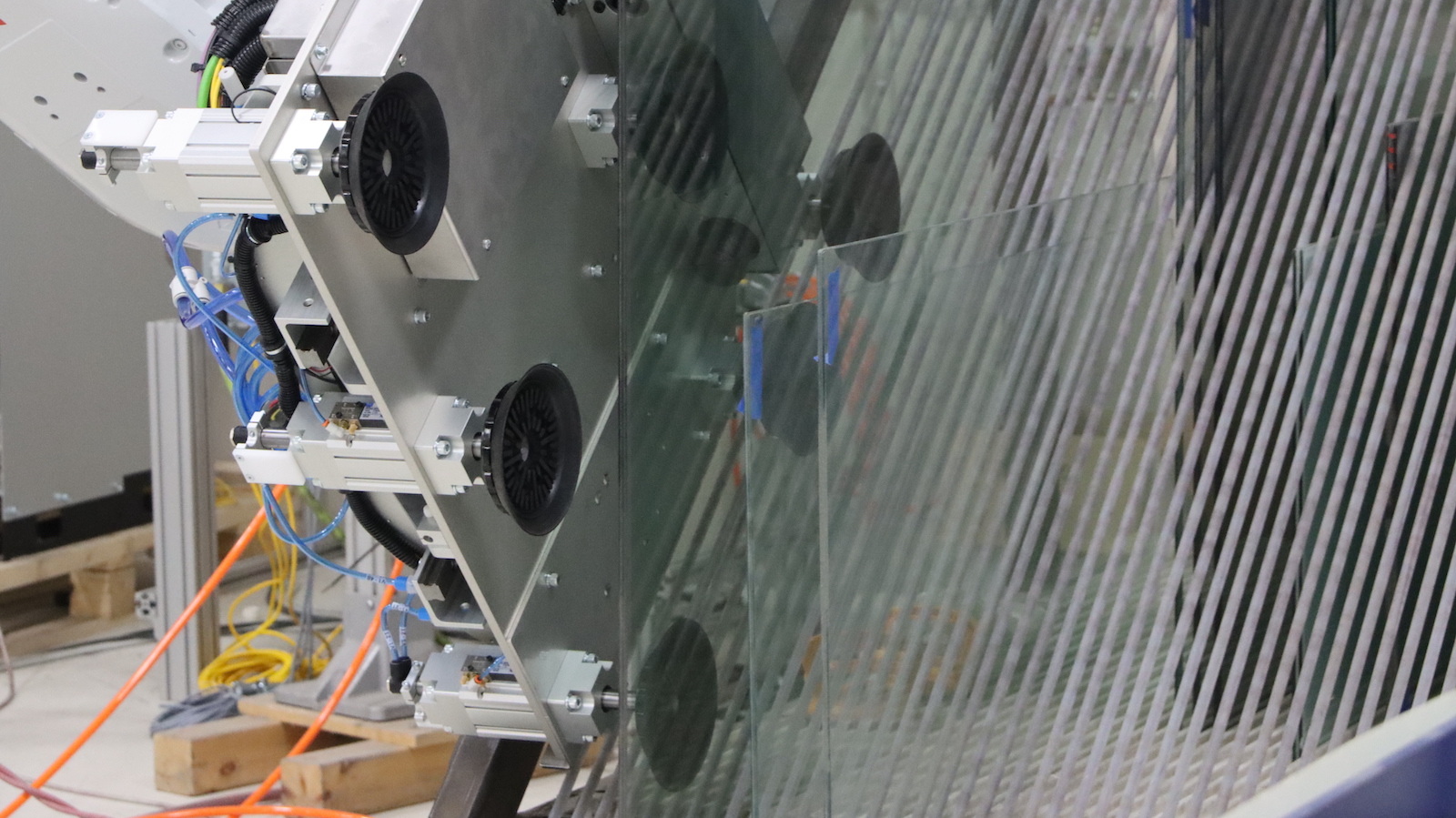

Automation Challenge: Glass Industry Harp Rack Loading

Learn how QComp’s innovative harp rack unloading automation improves glass industry safety, reduces risks, and boosts precision and productivity.