Michael Combs

Applications Engineering Manager

Michael Combs began his career in Louisville, KY with Lantech, where he spent a total of seven years—including internships and part-time work during college. Most of his time was with the Core Products Engineering Team, a group responsible for everything from life-cycle testing and part obsolescence to building new assembly lines and integrating robotic systems.

One of Michael’s largest and most formative projects was the integration of a robotic welding cell—a first for Lantech. As the sole engineer on the team, he took on everything from designing welding fixtures and redesigning parts for automation to programming the robot itself. This hands-on experience sparked his lasting interest in robotics.

In early 2020, Michael moved to Wisconsin to be closer to family and joined QComp Technologies as an Applications Engineer. Since then, he’s provided technical solutions, layouts, pricing, and proposals for both the sales team and customers directly. His leadership and expertise led to a promotion to Team Lead in 2023 and an invitation to join QComp’s Leadership Team in 2024.

Credentials / Certifications / Education

- Master of Business Administration in Data Analytics – March 2027

- Bachelor of Science in Mechanical Engineering

History with the Company

At QComp, Michael has focused on building stronger foundations for how the Applications Engineering team presents solutions to customers. His current work centers on developing standardized processes and proposal formats that make QComp’s engineering approach clearer, faster, and more consistent across projects.

Since joining QComp, Michael has seen the Applications Engineering team evolve significantly—through new talent, shifting markets, and fresh ideas. Having worked alongside multiple engineers and sales partners over the years, he’s played a key role in keeping technical excellence and collaboration at the center of how QComp serves its customers.

Areas of Expertise

Quick-turn quoting, solution development, and a deep understanding of QComp’s full system capabilities—from concept layouts to final system design. Known for delivering accurate, detailed proposals under tight timelines while aligning technical solutions with customer goals.

If you need automation and don't buy it, then you will ultimately find that you have paid for it and don't have it.

Michael Combs

(based on a quote by Henry Ford on machinery)

Why QComp?

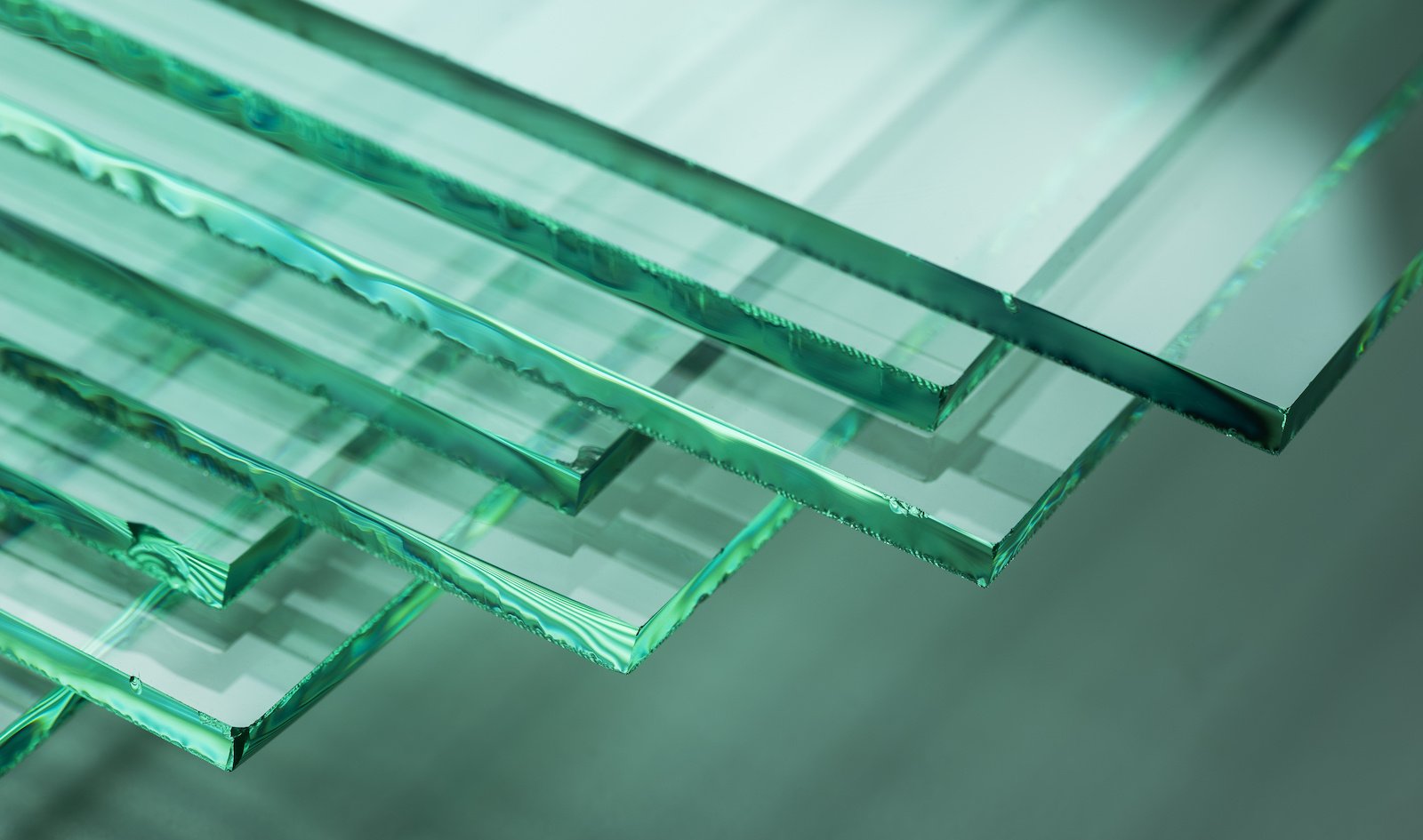

My favorite part about working at QComp is the variety of projects I get to be involved in—and watching each one come to life on our shop floor. One week I might be quoting a glass-handling system, the next it’s a wet wipes or food-packing line. Every project is different, and that constant challenge keeps the work exciting. There’s nothing better than seeing a concept I helped develop turn into a fully running system.

Articles from Michael

Before You Sign a Contract: 5 Smart Questions to Ask an Automation Partner

Before signing an automation contract, ask these 5 smart questions to ensure safety, reliability, and long-term ROI from your robotics partner.

4 Main Types of Flat Glass Suitable for Robotic Automation

Understand the 4 main types of flat glass — float, tempered, laminated, insulated — and how robotic handling improves efficiency and reduces breakage.

Common Cobot Safety Risks & Prevention Tips

What is the difference between a cobot vs. robot, and what safety features need to be implemented to prevent injuries? Learn about cobot safety tips.